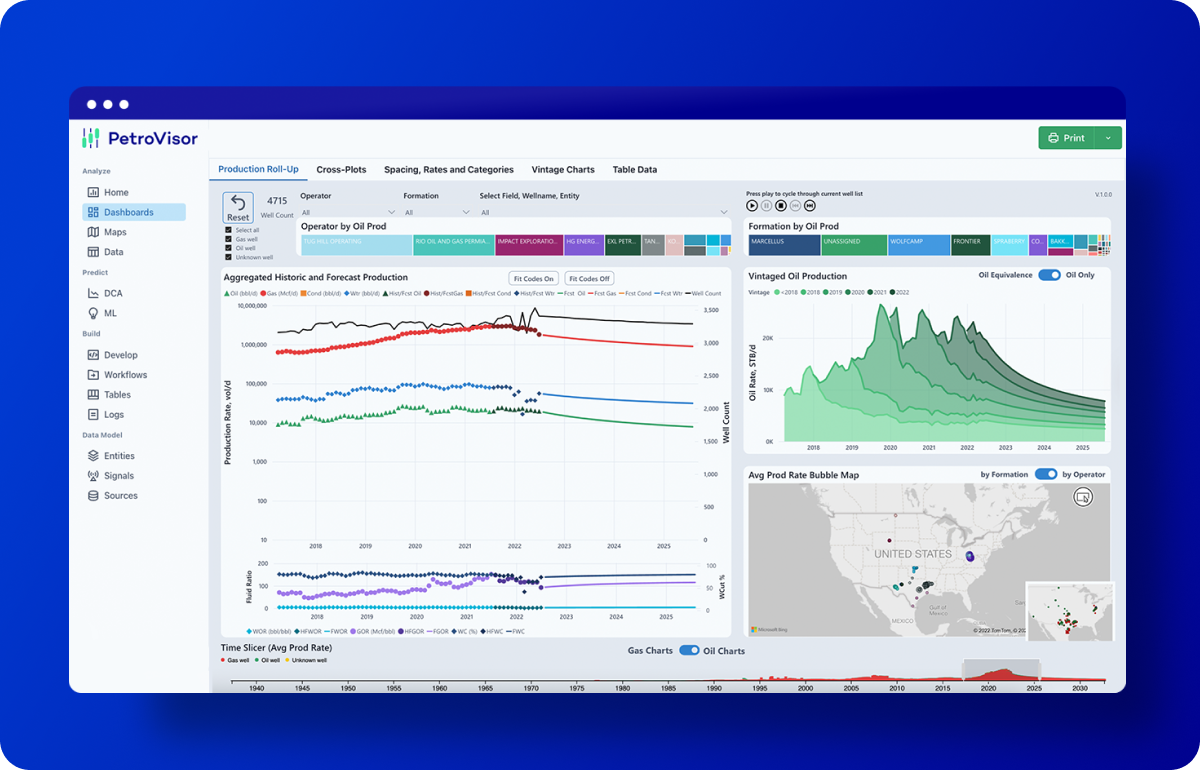

Technical Well

Problem Detection

Detect general technical problems based on production or injection rates, e.g. sudden changes in production rates.

-

Enable a production operator or production foreman to efficiently identify possible production issues in day-to-day operations