Using PetroVisor™ to Accelerate Profitability

PetroVisor™ reduces tedious and costly manual efforts to de-silo data and make use of it. More importantly, PetroVisor™ enables E&P companies to do things that simply couldn’t be done before.

Solving Critical Problems for Operators

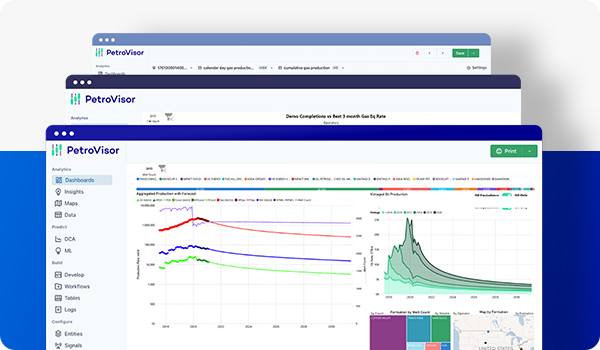

At its core, PetroVisor™ enables E&P companies to quickly and efficiently make data-driven decisions using a holistic asset management approach based on all available data. As new data or other systems are integrated, the decision-making algorithms are continuously updated, ensuring best-of-class decision-making capabilities at all times.

PetroVisor’s™ ability to consolidate and integrate disparate data systems in a scalable and flexible format brings significant value to operators. This functionality is the key feature enabling powerful analytic and workflow automation across multiple disciplines and functions.

Technology & Data Agnostic

When it comes to source and output data, PetroVisor™ was built to be agnostic. Because our SMEs understood that various organizations prefer different reservoir/petroleum engineering software, ERP systems, and so on, PetroVisor™ was designed to be an independent, open platform that can ingest data from all systems and data sources. PetroVisor™ provides a solution that is compatible with any database or legacy system, including all major service providers.

Scalable & Flexible

PetroVisor™ uses a data mapping wizard to enable rapid implementation of software and ensure the links between databases stay in place once implemented. New data is brought into the platform and is seamlessly analyzed via existing workflows – new databases can be added without disturbing existing data links. Functions can then be migrated to the cloud and links will stay intact for continued analytics. PetroVisor™ also completes analytics with artificial intelligence that improves via machine learning. As the software recommends actions that are executed, actual results are compared to expected results, and algorithms are adjusted to improve future forecasts. No competing solutions allow the ability to integrate all data sources with scale and the flexibility to take in new data, adjusted to actual results.

Cost-Effective Implementations

PetroVisor™ implementations are cost-effective and leverage the customer's SME resources and knowledge base to minimize the burden placed on IT teams. Implementations are typically completed within weeks with only one to two customer personnel. PetroVisor™ implementation also requires significantly less time, personnel, and ultimately investment when compared to other solutions with similar capabilities – which often require large integration efforts, project teams, and multi-million dollar investments.

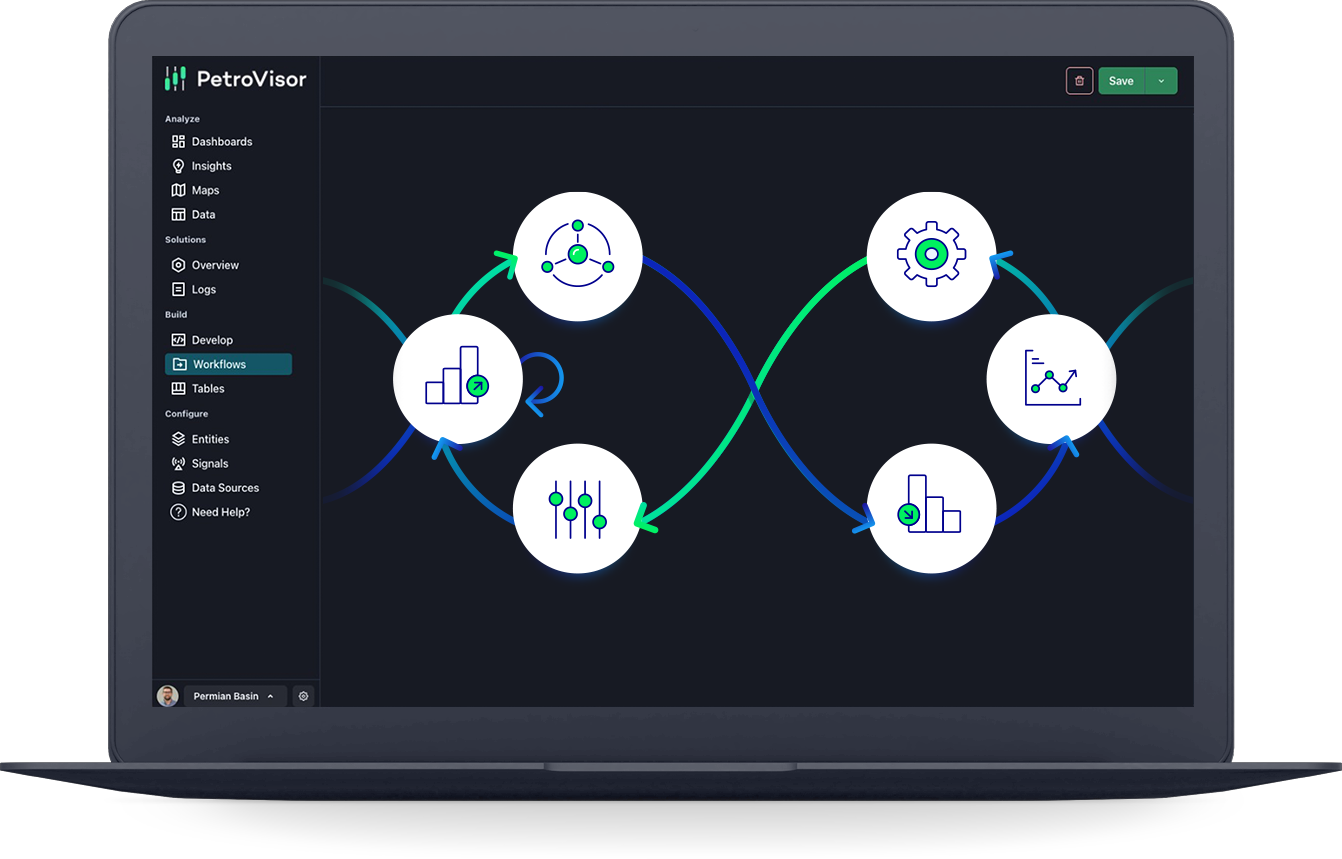

Configurable Workflow Automation

Most technologies require specially trained power, super users, or data scientists to realize the system’s full potential. PetroVisor™ users can quickly query required data sets and output formats. P# understands the units and measurements that are used in the industry and allows powerful integrated spatial queries as well as easy transformations (unit conversions, pivoting, currency changes, etc.). The language uses built in "IntelliSense" to suggest functions and find syntax errors. Training on P# is available during implementation and the language is fully documented for users. Alternatively, the widely used Microsoft R language is fully integrated with native support in PetroVisor™ for data scientists, technically advanced teams, and existing data analytic operations as well.

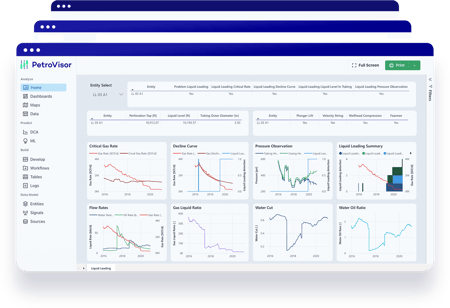

Intuitive & Easy-To-Use

PetroVisor™ has developed dashboards tailored for each workflow, with each user’s expertise and role taken in to account to ensure the most relevant data and analytics are front and center. The user interface is also customizable so that it can be adjusted to the user’s specific preferences, ensuring ease-of-use. The platform prioritizes user experience to allow users of different skill levels with the ability to use the system with little to no training. By implementing modern design principles, PetroVisor™ is uniquely positioned to displace complicated and expensive systems with its powerful but “simple” interface, focused on performing complex operations with as few interactions as possible. PetroVisor™ can also integrate with Microsoft Teams, enabling users from multiple disciplines to work and collaborate in one environment versus multiple siloed workspaces. By operating within Teams, PetroVisor™ enables rapid cross-discipline review of analytics and opportunities to speed up decision making. Our vision for PetroVisor™ in Teams is to become the critical, central application where customer decision-making, analytics, and collaboration take place daily. To encourage that, our platform leverages up-to-the-minute data to identify problems as well as opportunities, making it the perfect command center for oil and gas producers.

DATAGRATION WHITEPAPER

Change Management in Oil & Gas: Steps to Ensure Your Digital Transformation Sticks

Change is not a quick fix, nor is it a temporary solution. For change to be effective, it must be an integral part of a long-term business strategy and tied to quantifiable results.

.png?width=250&height=310&name=mockup%20(1).png)

Producing Impactful Results

With PetroVisor™, operators are able to streamline workflows by aggregating and integrating data from disparate systems. By linking these databases into one cloud-based or on-premise platform, PetroVisor™ is then able to offer built-in applications to complete real-time analytics.

Increase Operating Netbacks

Lower lifting costs by

through advanced problem detection and lift optimization that uses AI and machine learning.

Reduce Data Management Costs While Increasing Data Utilization

reduces the industry norm and saves you hundreds of thousands of dollars.

Increase Manpower Efficiencies

to all manpower required for well reviews.

Discover What’s New in the PetroVisor™ Platform

Take a deep dive into the latest PetroVisor™ release. New features are continuously being developed, deployed, and updated, ensuring our customers always have the latest and most up-to-date version of PetroVisor™.