Maximizing revenue and production are common goals for any O&G company, both of which are more easily achieved with the right data. What used to be time-consuming and nearly impossible to calculate in real-time by hand, PetroVisor™ automates with clarity and cohesion.

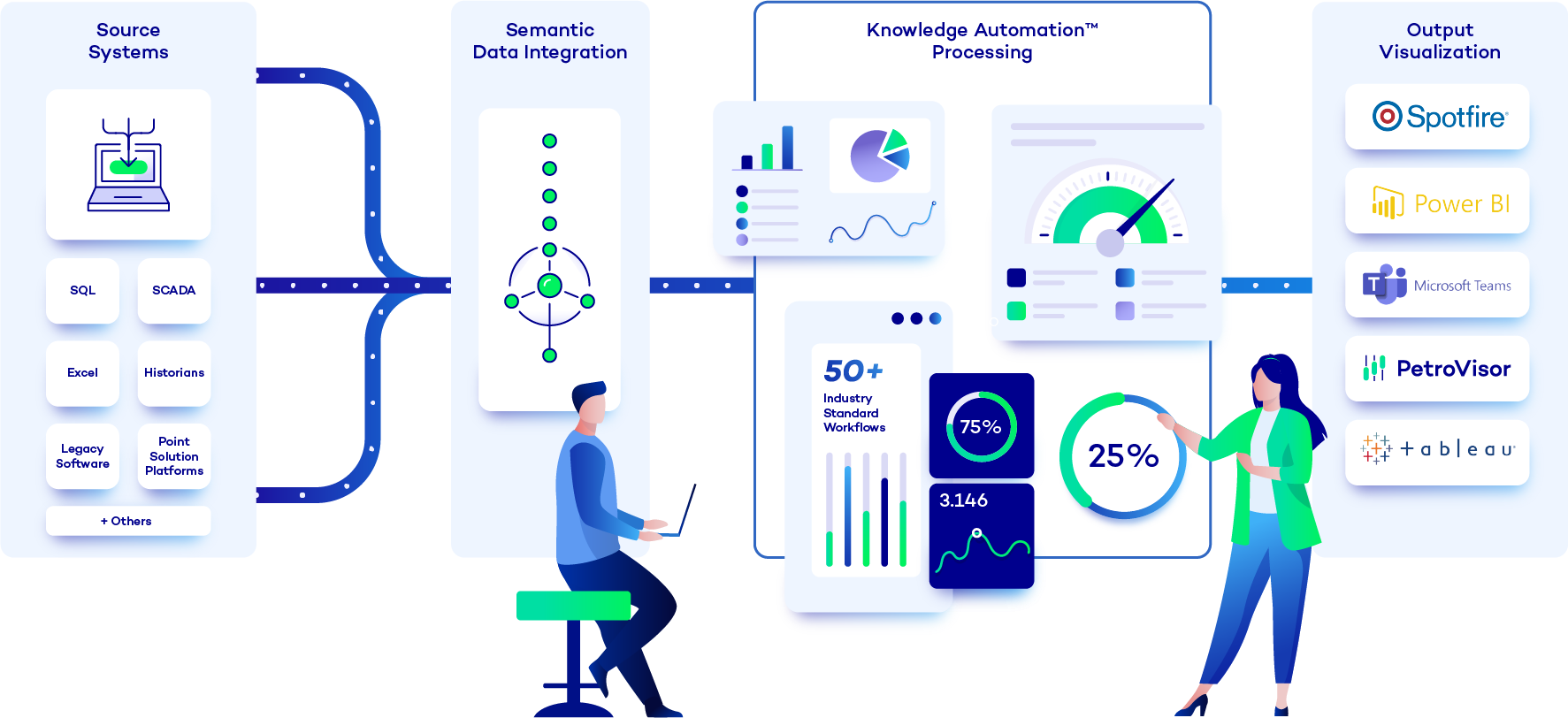

PetroVisor™ integrates data from reservoir to topside equipment to capture the constraints and potentials throughout the upstream value chain. As a result, operators can gain better, faster, more reliable insight into their resources to improve their production planning and protect the bottom line.

Here’s a closer look at its top features:

Constraint Management

PetroVisor™’s Constraint Management product supports business intelligence for decision making. By staying focused on the most profitable and important tasks, companies can make the best use of their resources in the moment without the guesswork.

Depending on the constraint of each asset, PetroVisor™ uses data-driven, knowledge-driven and physics-based models to monitor performance, run root-cause-analysis and provide advice to maximize system capacity through an optimized management of the constraints.

For visual insight and ease of use, you can integrate third party software with PetroVisor™ or use the platform’s built-in modeling tools as an integrated asset management system. Machine Learning and Artificial Intelligence tools enable customers to build their own advisory systems within the platform, including a feedback loop feature to evaluate decision impact and improve the asset model. Objective functions can easily be adapted to changing economic and market demand environments.

When companies can increase the accuracy of forecasts (and therefore their decision-making), PetroVisor™ can run autonomously to minimize manual intervention and reduce unplanned downtime and underperformance significantly.

Topside Business Case Value

An important business case value of Constraint Management is to optimize improvements on the topside facility PetroVisor™ accomplishes this by aligning asset reliability and maintenance spend with more efficient and broader data access. Because each set of independent conditions can lead to events that create non-productive time, using PetroVisor™’s available tools to better analyze and act upon data delivers impacts at both Asset and Global levels.

Examples of deliverable results through the PetroVisor™ platform include:

- Enhance surveillance/operator care to address degradation modes not identified in equipment strategies or maintenance plans

- Identify conditions that lead to events

- Update equipment strategies to drive efficiencies in OPEX and CAPEX

- Utilize fleet operating data to drive project decisions (including equipment selection)

- Drive improvements in vendor performance

- Perform internal benchmarking to compare across assets

- Enable fleet analytics

The degree to which of each of these deliverables is determined by a number of factors, including but not limited to the following:

- Ability to maximize production capacity while minimizing product costs

- Availability of low-cost technology

- Flexible, extensible and reusable components and functionalities increase with growth

- Transparency and collaboration speed up the ability to make timely decisions decreasing costs

- Collaborative decisions enabled globally

- Ability to manage fleet dynamics

When the right data is prioritized at the right time, O&G companies have a better chance of making value-adding decisions in the moment that can trigger a number of other positive effects throughout production.

PetroVisor™ Success Criteria

More important than the data itself is the results it delivers, both in terms of production and in your bottom line. To measure this success, every project should start with a clear understanding of each phase of the data ingestion, curation and consumption. Companies need tangible KPIs and workflows that demonstrate optimization to reduce equipment downtime, as well as provide broad and efficient access to data sources. Last but not least, any barriers to achieving integration should be identified and accelerators should be put into place to support deployment of additional use cases.

Schedule a demo today to see how PetroVisor™ simplifies constraint management for oil and gas companies and connects topside equipment to the reservoir for better performance.

November 23, 2020